About our Company

Open Joint Stock Company Kobrin Butter and Cheese Making Factory is a company with 80 years of experience and its unique production traditions. We can proudly remember every year of our Factory's history. We have something to tell and something to be proud of!

When creating this website, we sought to provide you with the opportunity to learn the rich history of our Company and the main stages of our team formation, to become familiar with all our products and to receive reliable information about our new products and relevant news about the Company's life.

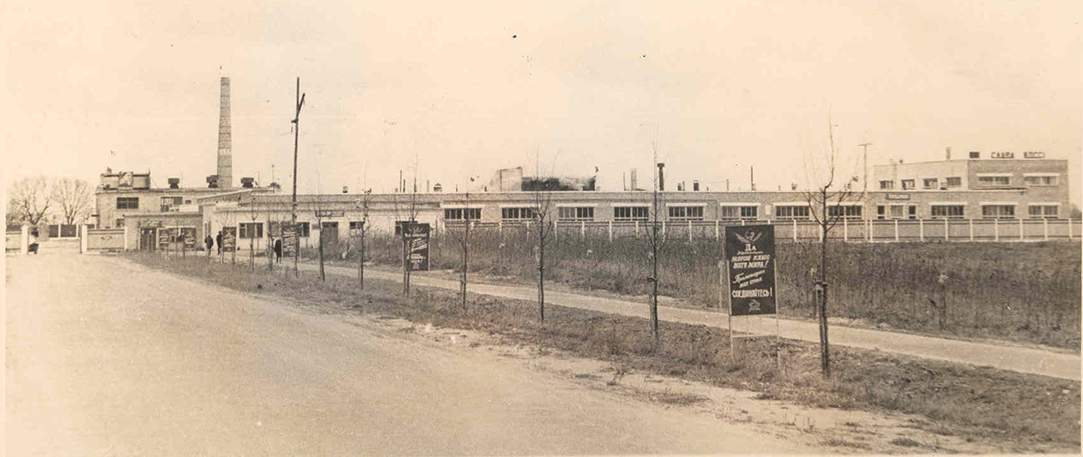

In October 1939, Kobrin City Dairy Mechanized Factory was formed on the blessed Kobrin land and began produce dairy products. Since this year the history of modern Kobrin Butter and Cheese Making Factory JSC has begun. At the initial stage of its development the Factory together with all the Belarusian people suffered from the enemy occupation during the hard years of the World War II. It was brutally plundered and destroyed by the fascist invaders.

The team of the Factory went through this tragedy heroically and after the war, when Belarus was liberated, in 1944, in such difficult work environment the Factory began to produce its regular, but at the same time very necessary for the people of Belarus, products: butter, curd and even cheese.

Due to the dedicated work of the Company's employees and the support of the state, the Factory was reconstructed and increased its annual production volumes. One of the biggest milestones of the history of our Company was 1968 when new production premises were introduced; and they served as the basis for the further production development.

In the mid-1970s, the industry leadership pinned high hopes on the Company. The reason was that Kobrin Butter and Cheese Making Factory was located in a strategically important area of the Brest region. There is a well-developed road infrastructure and large raw materials processing and delivery centers nearby.

In 1996, the Factory acquired the status of an open joint-stock company. And the Company started following its continuous path of modernization.

All the products of our Company are produced from selected natural high-quality milk. We carefully analyze the quality of the raw materials supplied to our Factory. The monitoring is carried out continuously, so specialized laboratory equipment was purchased for each farm: a quality analyzer and an analyzer of milk somatic cell count. To preserve the quality of the harvested milk during its transportation, a special Transport Department has been created, it has more than 30 new milk tankers. One of the most important goals of the domestic dairy production is to provide farms with refrigeration equipment. Thus, from 2000 through the present, more than 130 refrigeration systems have been mastered and brought into operation in the farms of the region.

During the period from 2012 till 2013, the Factory purchased processed cheese-making equipment, a new cheese packaging line, and curd-making equipment. The Factory is constantly working on introducing new innovative packaging into production. The Factory keeps following the path of modernization.

In 2015, the Company implemented a large-scale investment project: the construction of a modern Cheese-Making Department was completed. Its introduction into service allowed us to expand the cheese range significantly and to maintain a stable position in foreign and domestic markets.

Additional cheese-making capacities became operational in 2018: an automatic cheese packaging line, which allows to pack cheese in boxes automatically, and a robotic packaging line for stacking formed boxes on pallets were installed. Then pallets stacked with cheese arrive at our warehouse, where the products are identified. All this made it possible to replace manual labor and to increase labor productivity.

Modern types of packaging materials are used for producing new types of products. This is complemented by a unique design of each product line. Maasdam and Mont Blanc cheeses packed in polymer coating is one of the latest developments of the Company. The label is printed on so-called sulfite paper. To optimize the production of cheese in polymer coating, a line for labeling, polymer coating and “banding” has been purchased. It provides an additional degree of protection for our finished products and serves as an additional competitive advantage, plus it gives the opportunity to attract the interest of retailers and the attention of ultimate buyers.

A new Cheese-Making Department has begun operating at Kobrin Butter and Cheese Making Factory JSC where the Austrian automated line for the production of hard and semi-hard cheeses manufactured by BERTSCH-LASKA has been installed. All the processes of cheese production are carried out in a closed process, the equipment is characterized by high automation level and minimal contact of the products with the external environment. Due to the installed equipment, which includes a universal press machine, it is possible to produce bulk cheeses and reservoir cheeses, Russian and Dutch cheeses, and elite European cheeses. The line is equipped with equipment that allows to produce cheeses of various shapes. Besides traditional cheese wheels and blocks, it is possible to produce cheese bars, squares, and etc.

In the 4th quarter of 2018 and in the beginning of 2019, the Department for the Powder Milk Product Production was modernized and a new, more effective vacuum-evaporator system with mechanical vapor recompression (its capacity is 10 tons of evaporated moisture per hour) was installed. It allowed to increase the production of whey powder and to increase its export.

Moreover, the Company also has POLPAK 3000С4 automatic filling and packaging machine for mayonnaise and mayonnaise sauces. It made it possible to reach the new production volume of mayonnaise and mayonnaise sauces, as well as to increase labor productivity and out-turns.

Today, 5 systems have been imposed and certified by Kobrin Butter and Cheese Making Factory JSC:

1. Quality Management System for the compliance with the requirements of STB ISO 9001-2015.

2. Food Safety Management System based on Hazard Analysis and Critical Control Points (HACCP system) for compliance with the requirements of STB 1470-2012.

3. Environmental Management System for compliance with the requirements of STB ISO 14001-2017.

4. Labor Protection Management System for compliance with the requirements of STB 18001-2009.

5. Food Safety Management System for compliance with

the requirements of STB ISO 22000;

The Company has implemented the Automatic Infrared Test and Inspection System (AITIS) which allows to control the production process – from incoming raw materials to the finished products.

Nowadays, Kobrin Butter and Cheese Making Factory is a town-forming, modern high-tech enterprise equipped with the latest automated, energy-efficient equipment and highly qualified specialists, having its own traditions and high production standards.

Milk processing capacity of the Company comes up to 500 tons per day. The Company processes about 8% of milk of the region and up to 2% of milk on the general scale of the Republic of Belarus. Every month Kobrin Butter and Cheese Making Factory JSC provides financial assistance in the form of the milk supply prepayment to the agricultural enterprises of the raw material zone.

The product range includes more than 150 types of dairy products of the following product lines: cheese, butter, mayonnaise, curd, sour cream, yogurt, and ice-cream.

More than 90% of the produced cheese is exported by the Company. The export supplies are made to such countries as Russia, Uzbekistan, Turkmenistan, Kazakhstan, and Ukraine.

The high and stable quality of our products has been confirmed many times by the Prizes of the Government of the Republic of Belarus, different awards, gold medals and diplomas of republican competitions, international exhibitions and business forums. We are proud of the high marks and appreciate the recognition of our work by the industry experts, but the main reward for us is the appreciation of the quality and good reviews of our ultimate buyers, their true love and commitment to our brand. We are going to perfect the Company, to expand our supply geography and to produce new high-quality dairy products for you!

Sincerely yours, Kobrin Butter and Cheese Making Factory JSC.